When deliberating the qualities of various building materials, one pertinent question often arises: how durable is the material in question?

Polycarbonate sheet, a thermoplastic polymer, has gained popularity due to its impressive balance of lightweight and high impact resistance. However, when considering its applications, one must ask: is polycarbonate sheet breakable?

The Durability of Polycarbonate

Polycarbonate is lauded for its resilience. The material is frequently used in situations where a high impact resistance is crucial—for example, in the production of bulletproof glass, riot shields, and aircraft canopies. Its ability to withstand enormous force without breaking is one of its hallmark characteristics.

However, ‘unbreakable’ is a term that should be used cautiously. While polycarbonate is indeed tougher than many other plastics—such as acrylic—and can withstand significant force, it is not entirely indestructible. It can crack and break under extreme conditions or when subjected to stresses beyond its tensile limits.

Factors Influencing Breakability

Thickness

The thickness of the polycarbonate sheet is a principal factor in its breakability. A thicker sheet provides greater resistance to impact and is less likely to break. Manufacturers can produce sheets in varying thicknesses tailored to the requirements of specific applications.

Temperature

Polycarbonate maintains its integrity over a wide range of temperatures, typically from about -135 to 125 degrees Celsius. However, extreme temperatures can affect its performance. For instance, at very high temperatures, polycarbonate can become more malleable and less resistant to impact, potentially leading to breakage under force.

Ageing and UV Exposure

Over time, polycarbonate can degrade, especially with prolonged exposure to UV light. This degradation can lead to a reduction in its impact resistance. To counteract this effect, polycarbonate sheets are often treated with a UV-resistant coating to extend their lifespan and maintain their durability.

Chemical Exposure

Certain chemicals can also compromise the integrity of polycarbonate. Contact with abrasive chemicals can cause the material to weaken or become brittle, which in turn can make it more susceptible to breakage.

Comparing With Other Materials

It is instructive to compare polycarbonate with other commonly used materials, such as glass and acrylic, to contextualise its breakability. Glass, while offering a high degree of clarity, is much more likely to shatter upon impact.

Acrylic, on the other hand, is stronger than glass but still less impact-resistant than polycarbonate. Therefore, when toughness is paramount, polycarbonate is often the preferred choice.

Applications and Implications

The versatility of polycarbonate means it is utilised in a broad range of applications. In industries such as construction, automotive, and aviation, its impact resistance is a valued property. For instance, it’s used in the manufacturing of safety helmets, vehicle headlamp lenses, and transparent visors.

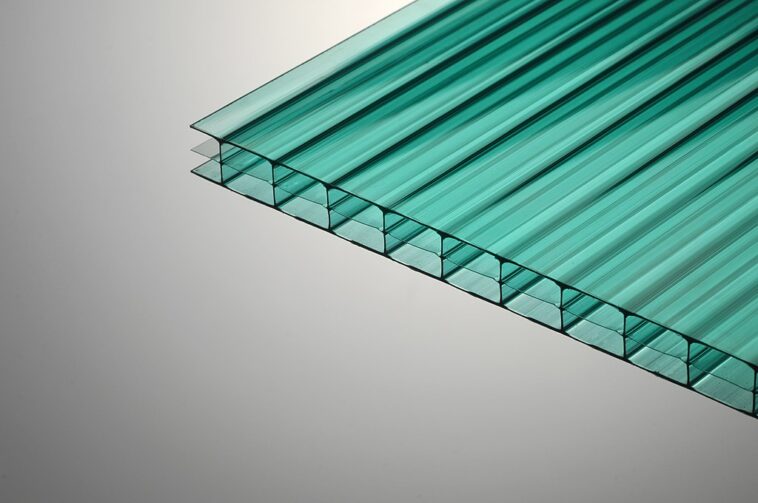

In construction, polycarbonate roofing sheets are popular for their durability and the fact that they allow light transmission similar to glass. Their resistance to breakage makes them a safer option in areas prone to severe weather conditions or where falling debris is a concern.

Maintenance and Care

Proper maintenance and care are essential to preserve the break resistance of polycarbonate. Regular cleaning with appropriate, non-abrasive cleaners can help maintain its strength. It’s also important to follow the manufacturer’s guidelines regarding installation and handling to avoid unnecessary stress that could predispose the material to breakage.

Conclusion

In conclusion, while a polycarbonate sheet is not entirely unbreakable, its level of durability is quite remarkable. It stands out as a robust material capable of enduring considerable stress and impact, which makes it suitable for a multitude of applications where safety and durability are critical.

Understanding the factors that affect its strength can help users maximise the lifespan of polycarbonate installations and use the material to its full potential. With thoughtful application and maintenance, polycarbonate continues to be a reliable choice for those in search of a material that combines clarity with an impressive resistance to breakage.

Frequently Asked Questions

1. What is a Polycarbonate Sheet?

Polycarbonate sheet is a type of thermoplastic that’s known for its strength and durability. It’s commonly used in various applications including construction, automotive, and protective gear.

2. How durable is Polycarbonate Sheet?

Polycarbonate sheets are extremely durable. They are impact-resistant and can withstand significant force without breaking, making them much stronger than materials like glass or acrylic.

3. Can Polycarbonate Sheets break?

While polycarbonate sheets are highly resistant to impact, they are not indestructible. Under extreme conditions or force, they can break, but it takes a lot more force to break a polycarbonate sheet compared to other materials like glass.

4. What types of impacts can Polycarbonate withstand?

Polycarbonate sheets can withstand impacts from hail, stones, and even resist breakage under the force of a hammer blow. They are often used in riot shields and bulletproof glass due to this property.

5. Are there different grades of Polycarbonate Sheets in terms of durability?

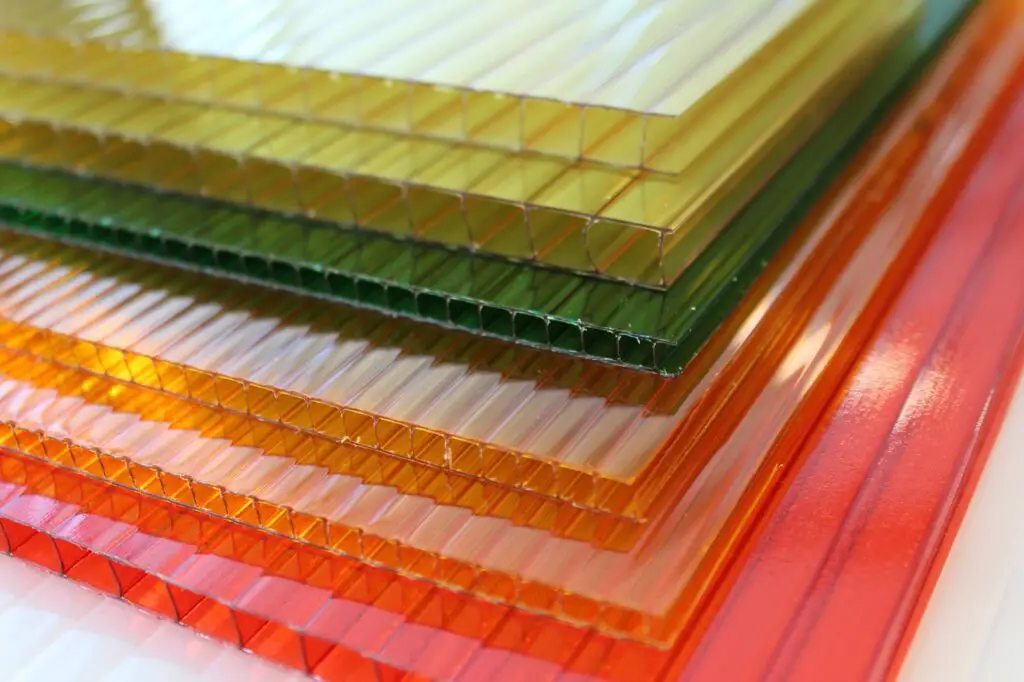

Yes, polycarbonate sheets come in various grades, each suited for different levels of impact resistance. Some are reinforced for use in high-risk environments, while others are more suitable for general applications.

6. How does temperature affect the breakability of Polycarbonate Sheets?

Polycarbonate maintains its impact resistance over a wide range of temperatures. However, extreme cold can make it more brittle, and extreme heat can cause it to soften.

7. Can Polycarbonate Sheets be used for safety purposes?

Absolutely. Their high impact resistance makes them ideal for safety applications, such as protective eyewear, face shields, and security windows.

8. How do I know if Polycarbonate Sheet is the right choice for my project?

Consider the environment and the type of impacts your project might face. If you need a strong, durable material that can withstand significant force, polycarbonate is an excellent choice.

9. How do I maintain Polycarbonate Sheets?

Polycarbonate sheets require minimal maintenance. Regular cleaning with mild soap and water is sufficient. Avoid using abrasive cleaners as they can scratch the surface.

10. Where can I purchase Polycarbonate Sheets?

Polycarbonate sheets are available at most hardware stores and specialty plastics suppliers. You can also find various suppliers online.